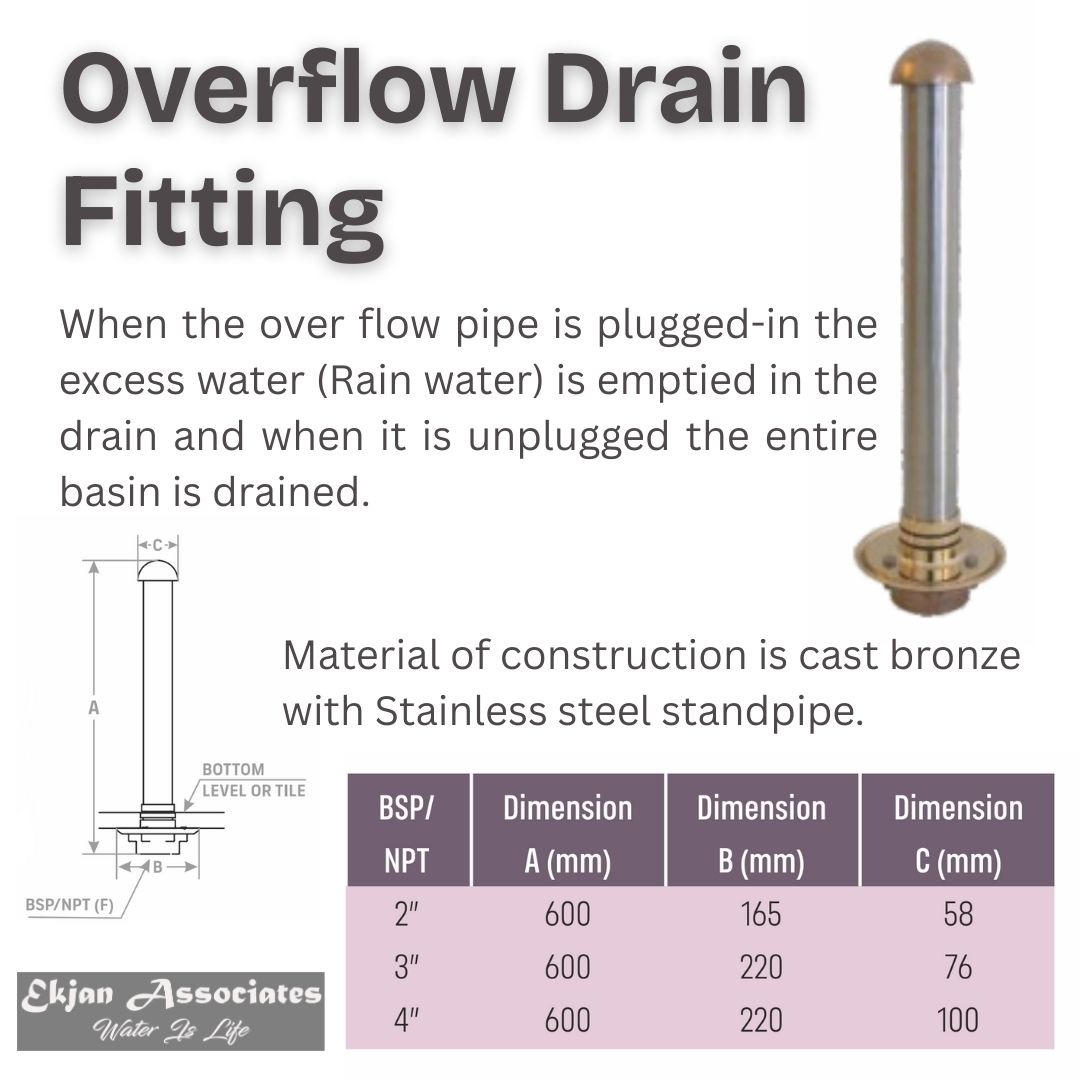

Overflow Drain Fittings for Fountain Ponds: Essential Water Feature Components Fountain ponds require precise water management to maintain optimal water levels and prevent overflow damage. Overflow drain fittings are critical components that ensure your water feature operates smoothly while protecting surrounding areas from water damage. How Fountain Overflow Drains Work These specialized fittings operate on a simple yet effective principle. When the overflow pipe is plugged in, excess water from fountain operation, rainfall, or overfilling is safely emptied through the drain system. When unplugged, the entire pond basin can be drained for maintenance, cleaning, or winterization. Premium Construction for Water Features Quality fountain overflow fittings feature cast bronze construction with stainless steel standpipes, providing exceptional durability against constant water exposure, algae growth, and varying weather conditions. This robust construction ensures your water feature continues operating reliably for years. Available Sizes for Different Pond Applications These fittings come in standard BSP/NPT threading: 2-inch fitting: 600mm length, 165mm width, 58mm height - ideal for smaller decorative fountains 3-inch fitting: 600mm length, 220mm width, 76mm height - perfect for medium garden ponds 4-inch fitting: 600mm length, 220mm width, 100mm height - suitable for large commercial water features Benefits for Fountain Pond Management The dual-functionality design prevents overflow damage during heavy rainfall while allowing complete drainage for seasonal maintenance. This makes them essential for both residential garden fountains and commercial water installations. Conclusion Proper overflow management is crucial for any fountain pond system. These durable fittings provide reliable water level control and maintenance flexibility, ensuring your water feature remains both beautiful and functional.