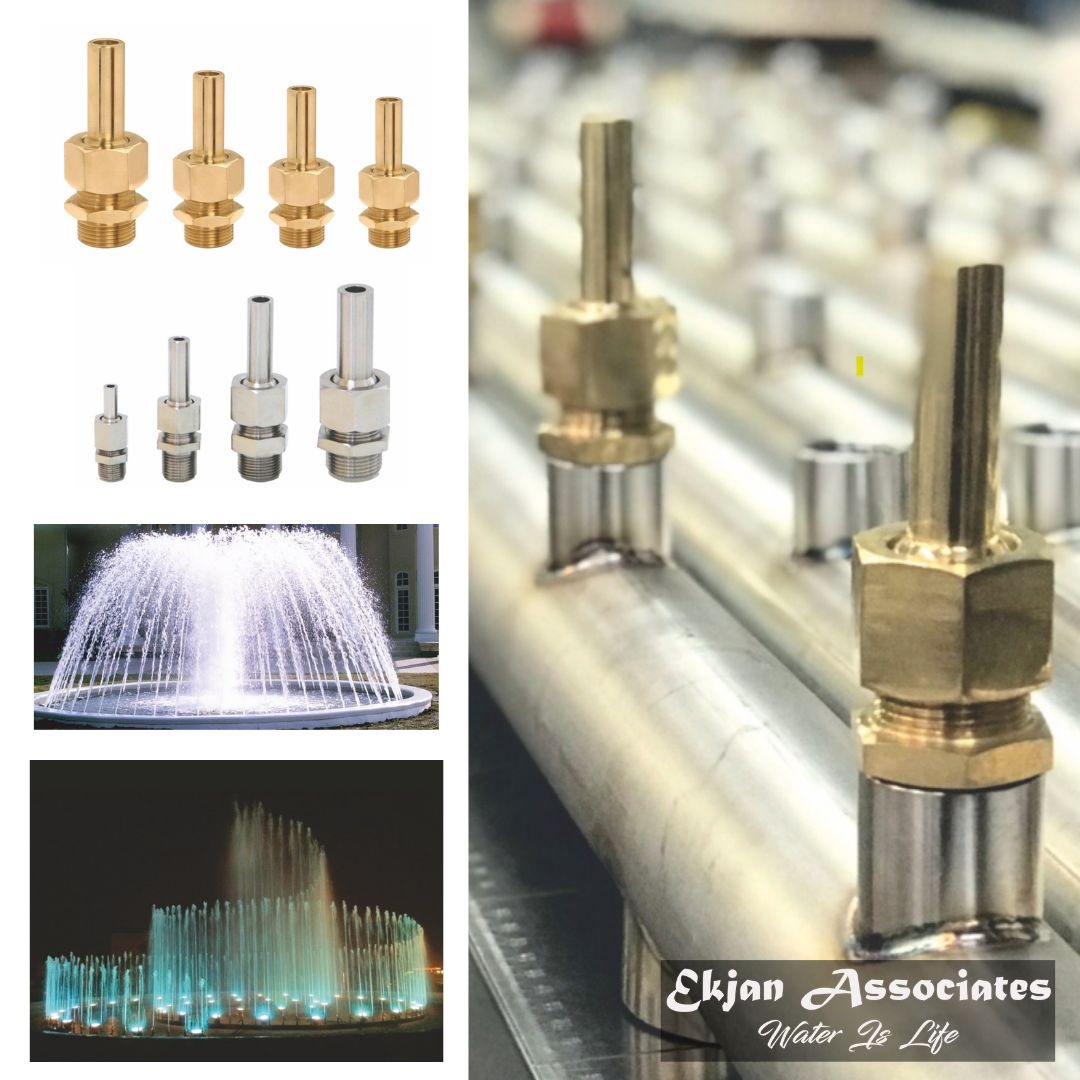

Fountain Nozzles

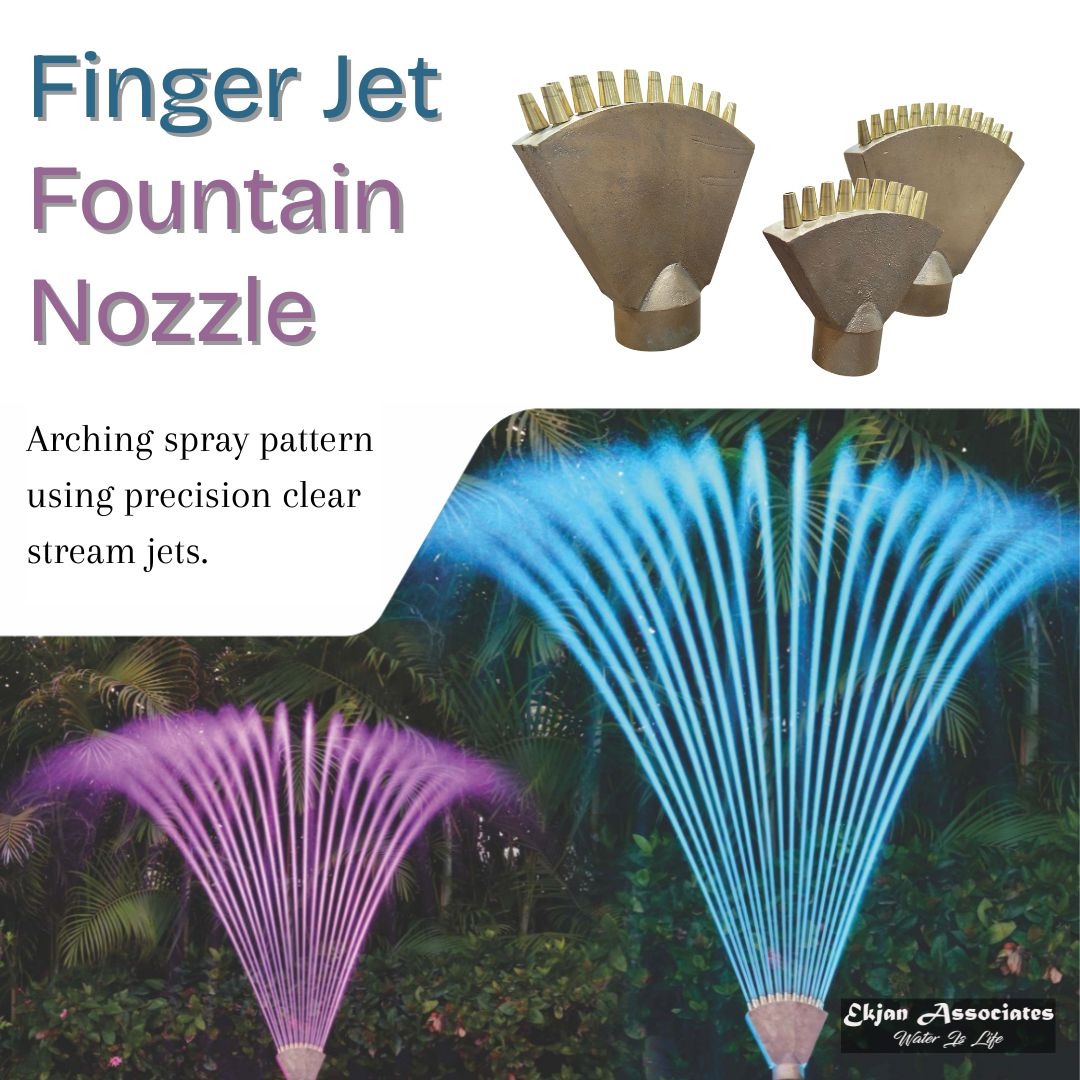

Transform Your Water Feature with Finger Jet Fountain Nozzles: The Art of Precision Water Display

When it comes to creating stunning water features that captivate viewers with their elegant beauty, few fountain nozzles can match the visual appeal and precision of finger jet nozzles. These remarkable devices create mesmerizing arching spray patterns using multiple precision-engineered clear stream jets, transforming ordinary water fountains into extraordinary artistic displays.

What Makes Finger Jet Nozzles Special?

Finger jet fountain nozzles represent the perfect marriage of engineering precision and artistic vision. Unlike traditional fountain nozzles that produce single streams or basic spray patterns, finger jets create multiple individual water streams that arch gracefully through the air, resembling the delicate fingers of a hand reaching toward the sky. This unique design creates a dynamic, ever-changing display that adds movement, sound, and visual interest to any water feature.

The magic lies in the precision engineering of each individual jet opening. Every stream must be perfectly calibrated to ensure uniform height, trajectory, and flow rate across all jets. This level of precision requires advanced manufacturing techniques and quality materials to achieve the stunning symmetrical patterns that make finger jet nozzles so popular among fountain designers and water feature enthusiasts.

Superior Materials for Long-lasting Performance

Understanding that fountain nozzles face constant exposure to water, chemicals, and environmental elements, finger jet nozzles are available in two premium material options designed for durability and longevity:

Stainless Steel 316 (SS316): This marine-grade stainless steel offers exceptional corrosion resistance, making it ideal for both fresh and saltwater applications. SS316 provides superior durability against chlorine, pH variations, and harsh weather conditions, ensuring your finger jet nozzle maintains its precision performance for years to come. The sleek metallic finish also adds a modern, professional appearance to any fountain installation.

Cast Bronze: For those seeking a more traditional or ornate aesthetic, cast bronze finger jet nozzles provide timeless elegance with proven durability. Bronze naturally develops a beautiful patina over time, adding character and sophistication to water features. This material choice is particularly popular for classical fountain designs, garden installations, and architectural water features where aesthetics are as important as performance.

Size Options to Fit Every Application

Finger jet nozzles come in three carefully designed sizes to accommodate different fountain scales and water pressure requirements:

1-inch Single Row: Perfect for smaller fountains, residential water features, or applications where a more subtle display is desired. This compact size delivers impressive performance while maintaining efficiency in water usage and pump requirements.

1.5-inch Single Row: The ideal middle ground for medium-sized fountains and commercial applications. This size provides enhanced water flow capacity and more dramatic spray patterns while remaining manageable for most pump systems.

1.5-inch Double Row: The premium option for large-scale installations and spectacular displays. Featuring two rows of precision jets, this configuration creates the most impressive and voluminous spray patterns, perfect for public fountains, commercial installations, and grand water features where maximum visual impact is desired.

Precision CNC Manufacturing: The Key to Uniform Excellence

The secret behind the stunning uniform spray arches of finger jet nozzles lies in advanced CNC (Computer Numerical Control) machining technology. Every finger jet nozzle is precision-machined using state-of-the-art CNC equipment, ensuring that each individual jet opening is manufactured to exact specifications.

This precision manufacturing process delivers several critical advantages:

Perfect Uniformity: Each jet opening is machined to identical dimensions, ensuring uniform water flow, pressure distribution, and spray height across all fingers. This uniformity is essential for creating the symmetrical, professional-looking displays that make finger jet nozzles so appealing.

Consistent Performance: CNC machining eliminates the variations that can occur with traditional manufacturing methods, ensuring that every nozzle performs exactly as designed, every time.

Quality Assurance: The precision of CNC manufacturing allows for rigorous quality control, with each nozzle meeting exact specifications before leaving the facility.

Longevity: The smooth, precise surfaces created by CNC machining resist mineral buildup and clogging, extending the operational life of the nozzle and reducing maintenance requirements.

Installation and Maintenance Benefits

Finger jet nozzles are designed with practical installation and maintenance considerations in mi

Price: 0 |

Payment Type: |

Available: False |

COD Available: False |

KYC Status: FAILED

Send Message