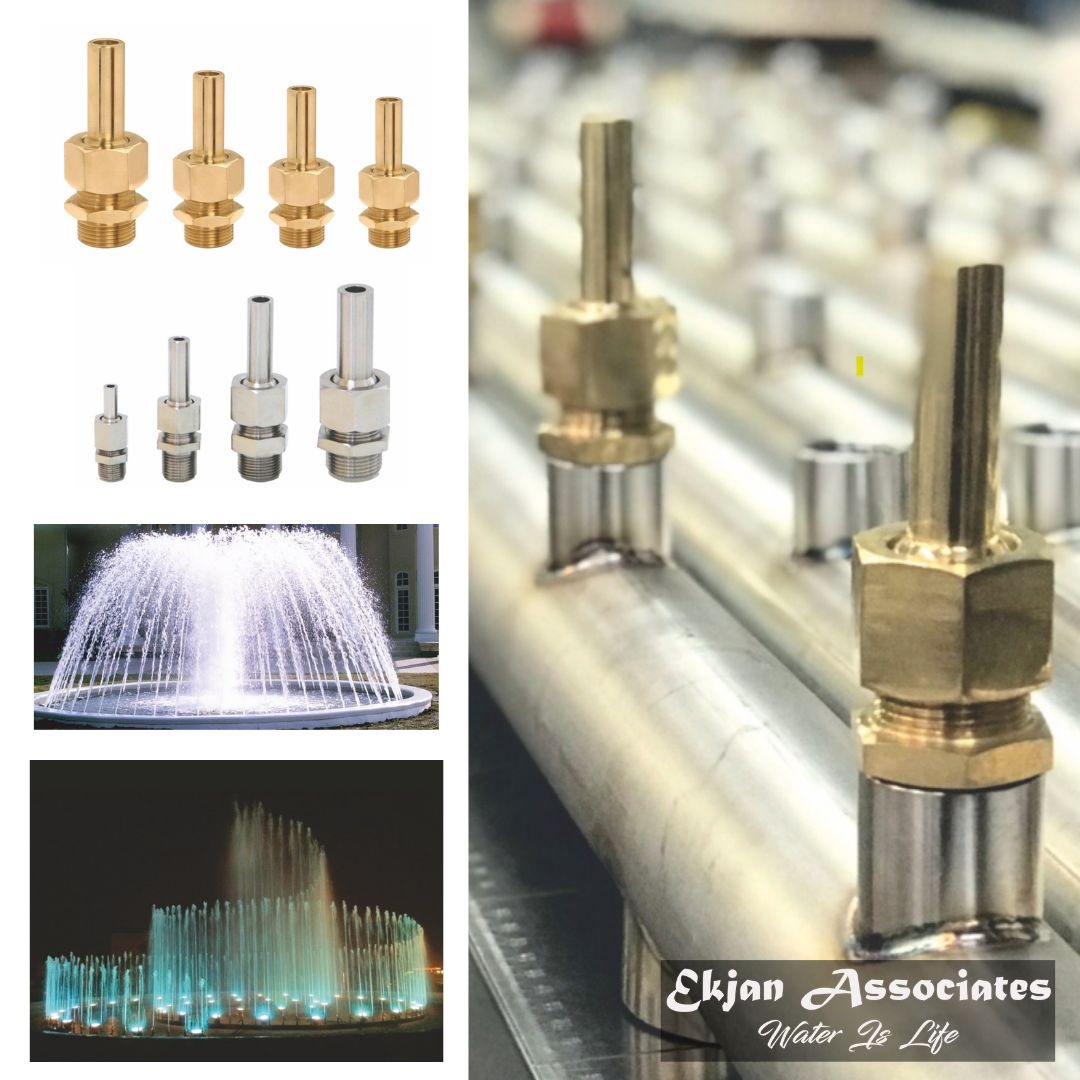

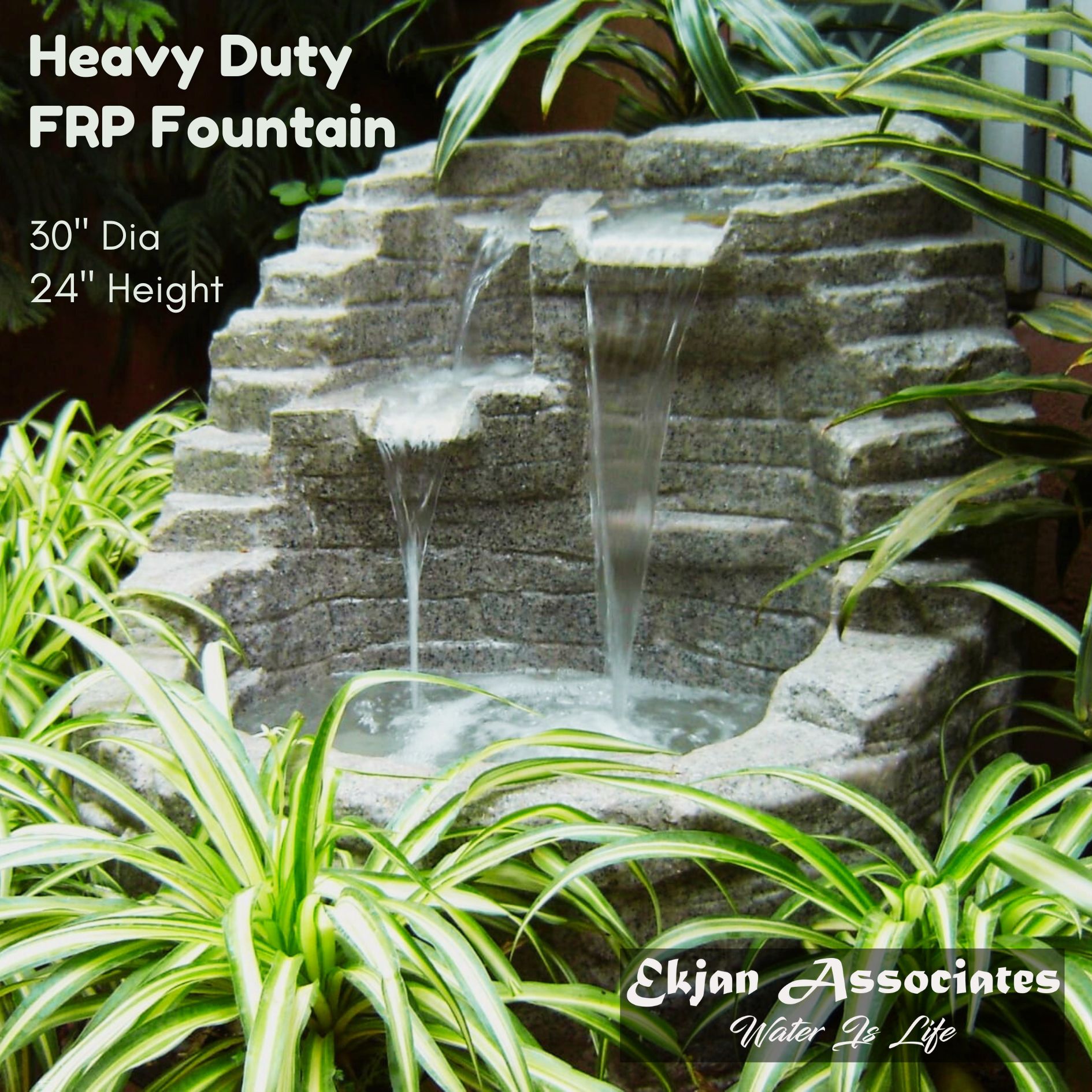

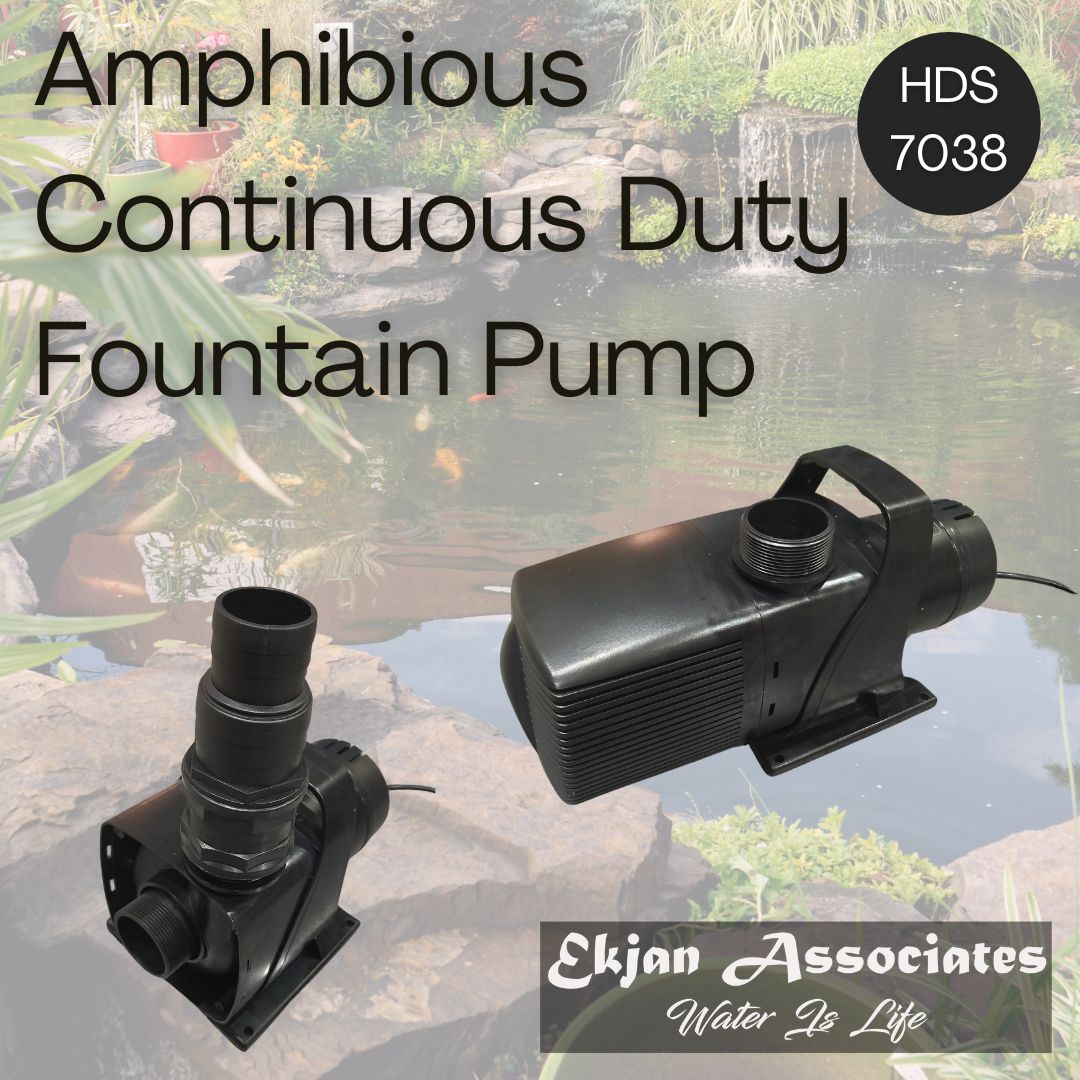

When it comes to creating breathtaking water features, precision and elegance are paramount. Enter the world of Adjustable Clear Stream Fountain Jets – the unsung heroes of spectacular fountain displays that transform ordinary water into extraordinary visual experiences. What Are Adjustable Clear Stream Fountain Jets? Adjustable Clear Stream Fountain Jets are specialized nozzles designed to produce clean, undistorted water streams that maintain their clarity and form throughout their trajectory. These small, tapered nozzles are engineered for precision performance, creating smooth, laminar water flows that appear almost glass-like in their transparency. Unlike traditional spray nozzles that create dispersed patterns, clear stream jets focus on producing concentrated, coherent water columns that maintain their structural integrity from source to destination. This unique characteristic makes them ideal for creating sophisticated fountain displays that demand visual precision. Key Features and Benefits Minimal Distortion Design The tapered design of these nozzles ensures that water maintains its clear stream characteristics with minimal turbulence or distortion. This results in: Crystal-clear water columns Consistent stream diameter Reduced splash and spray Enhanced visual appeal Precision Engineering Each nozzle is crafted for exact specifications, allowing fountain designers to: Control water flow rates precisely Maintain consistent performance across multiple jets Create symmetrical displays Achieve predictable water patterns Adjustable Performance The adjustable nature of these jets provides flexibility in: Stream height control Flow rate modification Pattern customization Seasonal adjustments Spray Ring Applications These nozzles are particularly designed for precision use with spray rings – circular arrangements that create stunning geometric water displays. When integrated with spray rings, adjustable clear stream jets can produce: Symmetrical Patterns Multiple jets arranged in circular formations create perfectly balanced displays where each stream complements the others, forming intricate water sculptures. Layered Effects By varying the height and flow rate of individual jets within a ring, designers can create multi-tiered displays that add depth and visual interest to any water feature. Dynamic Performances When combined with programmable control systems, spray rings with clear stream jets can create choreographed water shows that dance to music or change patterns throughout the day. Group Arrangements: Maximum Impact Clear stream fountain jets truly shine when arranged in groups. This design approach offers several advantages: Enhanced Visual Drama Multiple streams working in harmony create a more impressive visual impact than single jets, producing displays that capture attention and create lasting impressions. Flexible Design Options Group arrangements allow for: Linear formations for modern, architectural displays Circular patterns for classical fountain designs Random clusters for naturalistic water features Geometric shapes for contemporary installations Scalable Solutions Whether you're designing an intimate garden feature or a grand public fountain, group arrangements can be scaled to fit any space or budget requirement. Technical Considerations Water Quality Requirements Clear stream jets require clean, filtered water to maintain their transparency and prevent clogging. Regular maintenance ensures optimal performance and longevity. Pressure Management Proper water pressure is crucial for achieving the desired stream characteristics. Too much pressure can cause turbulence, while insufficient pressure results in weak, broken streams. Material Selection High-quality materials like brass or stainless steel ensure durability and resistance to corrosion, making these jets suitable for both indoor and outdoor applications. Applications and Use Cases Commercial Installations Hotel lobbies and courtyards Shopping centers and malls Corporate headquarters Public plazas and parks Residential Features Garden fountains Pool and spa enhancements Landscape water features Architectural water walls Special Events Wedding venues Festival installations Temporary exhibitions Seasonal displays Maintenance and Care To ensure optimal performance of adjustable clear stream fountain jets: Regular Cleaning: Remove mineral deposits and debris that can affect stream quality Pressure Monitoring: Maintain consistent water pressure for uniform performance Seasonal Adjustments: Modify settings based on weather conditions and usage patterns Professional Servicing: Schedule regular inspections by fountain maintenance specialists The Future of Fountain Design As technology advances, adjustable clear stream fountain jets continue to evolve, incorporating smart controls, energy-efficient designs, and sustainable materials. These innovations ensure that water features remain both environmentally responsible