2023-06-30T11:30:54

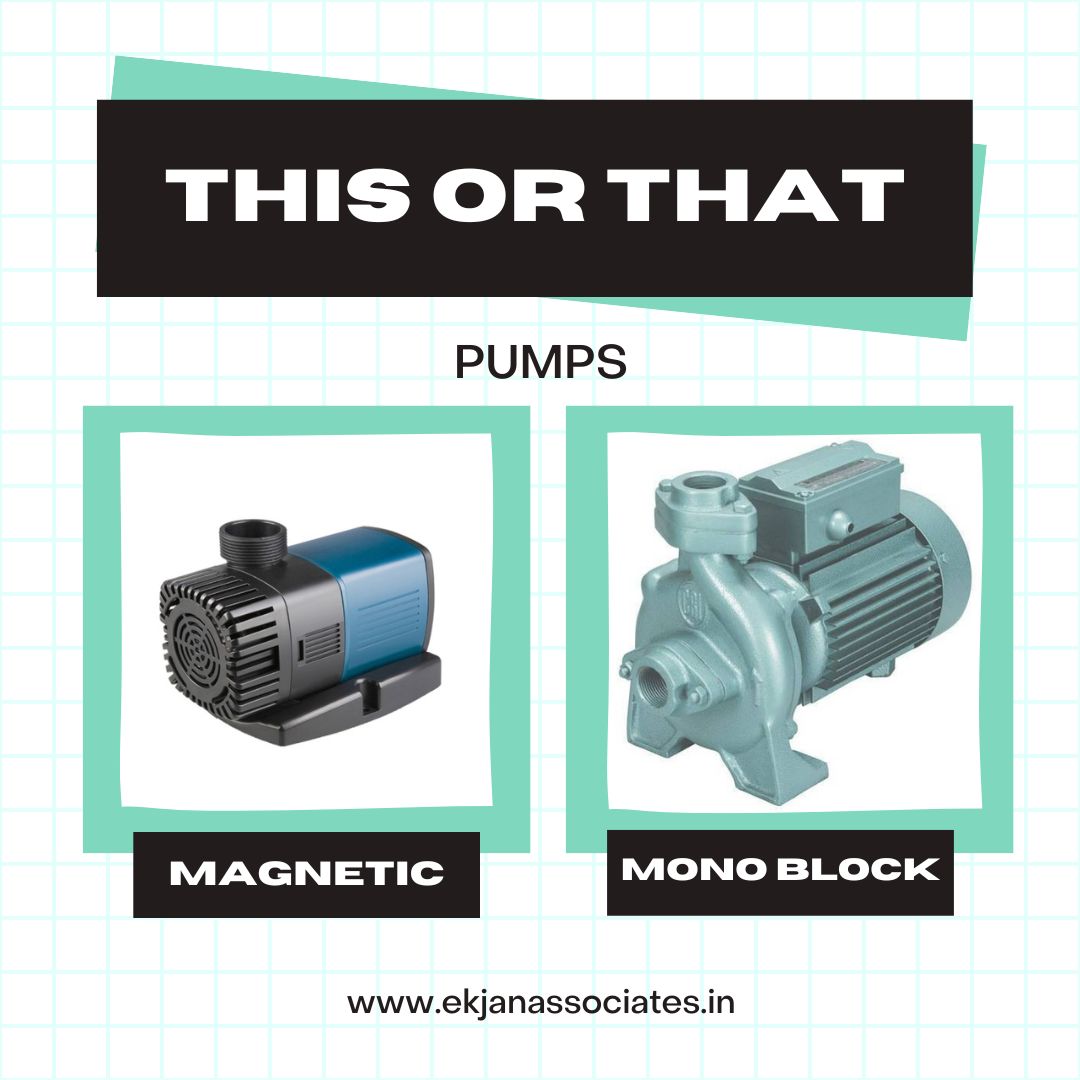

Magnetic impeller pumps and centrifugal pumps are two different types of pumps that operate on different principles. Here are the key differences between them: Working Principle: Magnetic Impeller Pump: Magnetic impeller pumps, also known as magnetic drive pumps or magnetically coupled pumps, use a magnetic field to drive the rotation of the impeller. The impeller is typically made of a magnetic material, and the magnetic field is generated by a set of permanent magnets or electromagnets. The rotating magnetic field transfers torque to the impeller, causing it to rotate and propel the fluid. Centrifugal Pump: Centrifugal pumps operate based on the principle of centrifugal force. They use an impeller with curved blades that spins rapidly within a casing. As the impeller rotates, it creates a centrifugal force that pushes the fluid radially outward. This radial motion increases the fluid's velocity, creating a pressure gradient and causing the fluid to be pushed out of the pump. Seal and Leakage: Magnetic Impeller Pump: Magnetic impeller pumps have a hermetically sealed design since the impeller is driven by a magnetic field without any physical connection to the motor. This eliminates the need for a traditional shaft seal, reducing the risk of leakage and eliminating the possibility of fluid contamination due to seal failure. Centrifugal Pump: Centrifugal pumps typically require a mechanical shaft seal to prevent fluid leakage along the rotating shaft. The seal can wear over time and may require regular maintenance or replacement. If the seal fails, it can result in fluid leakage, which can be a concern in certain applications. Efficiency: Magnetic Impeller Pump: Magnetic impeller pumps are known for their high efficiency. The magnetic coupling eliminates the need for a direct mechanical connection between the impeller and motor, reducing energy losses due to friction and mechanical inefficiencies. Centrifugal Pump: Centrifugal pumps are generally efficient but may have slightly lower efficiency compared to magnetic impeller pumps due to mechanical losses associated with the shaft, bearings, and seal. Application: Magnetic Impeller Pump: Magnetic impeller pumps are commonly used in applications where leak-free operation and the absence of contamination are critical. They are suitable for handling corrosive or hazardous fluids, high-purity liquids, or in situations where maintaining a sterile environment is necessary, such as in chemical processing, pharmaceuticals, and some industrial applications. Centrifugal Pump: Centrifugal pumps are widely used in various industries for general-purpose fluid handling. They are employed in applications like water supply, irrigation, HVAC systems, wastewater treatment, and many other scenarios where high flow rates and moderate pressure are required. In summary, magnetic impeller pumps and centrifugal pumps differ in their working principle, seal design, efficiency, and application. Magnetic impeller pumps utilize a magnetic field to drive the impeller and offer hermetically sealed operation with high efficiency, making them suitable for applications with strict sealing requirements. Centrifugal pumps, on the other hand, rely on centrifugal force and often require mechanical shaft seals but are versatile and widely used for various fluid handling applications. Magnetic drive pumps can be used for fish pond pumping solutions. Magnetic drive pumps offer several advantages that make them suitable for this application: Seal-Free Design: Magnetic drive pumps have a hermetically sealed design, which means they do not require a traditional shaft seal. This eliminates the possibility of seal failure and eliminates the risk of fluid leakage into the pond. It ensures that the water remains uncontaminated and prevents any harmful substances from entering the pond environment. Corrosion Resistance: Many magnetic drive pumps are made from corrosion-resistant materials such as plastic or stainless steel. This makes them suitable for use in water environments, including fish ponds, where exposure to moisture and chemicals is common. Efficient and Quiet Operation: Magnetic drive pumps are known for their high efficiency, which means they can effectively move water while consuming less energy. They also tend to operate quietly, which is beneficial for maintaining a peaceful environment in the fish pond. Controllability: Magnetic drive pumps often feature adjustable flow rates, allowing you to control the water flow according to the specific requirements of the fish pond. This flexibility is helpful in maintaining the desired water circulation and oxygenation levels for the health of the fish and other aquatic organisms. When choosing a magnetic drive pump for a fish pond, it is important to consider the size of the pond, the flow rate requirements, and the specific needs of the fish and plants. It's also advisable to select a pump that is specifically designed for use in aquatic environments to ensure optimal performance and longevity.

Have a question? Ask here!

Required fields are marked *