Why Local Cheap Fountain Nozzles Fail to Deliver: The Technical Truth Behind Fountain Performance

Water fountains are captivating architectural features that transform ordinary spaces into mesmerizing displays of water, light, and movement. However, the heart of any fountain system lies in its nozzles—the precision-engineered components that determine whether your fountain creates stunning visual impact or disappointing, uneven water patterns. Unfortunately, many property owners discover too late that choosing cheap, locally-sourced fountain nozzles leads to frustrating performance issues and costly maintenance headaches.

The Engineering Behind Fountain Nozzle Performance

Understanding why cheap nozzles fail requires examining the complex fluid dynamics at work. When water passes through a fountain nozzle, it undergoes rapid pressure and velocity changes that demand precise engineering. Quality nozzles are designed with specific internal geometries, flow coefficients, and manufacturing tolerances that ensure consistent performance under varying conditions.

Flow Uniformity and Internal Design

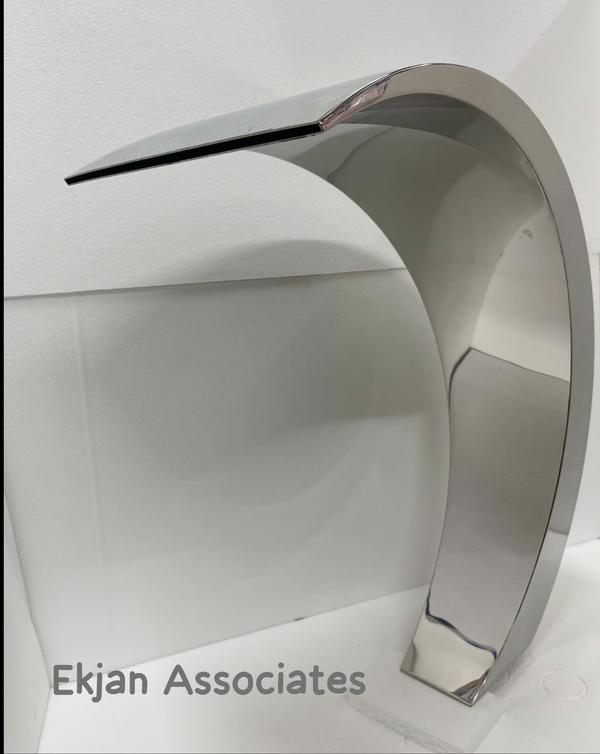

Premium fountain nozzles feature carefully calculated internal flow paths with smooth transitions and optimal angle calculations. The water enters through a controlled inlet, passes through precision-machined chambers, and exits through geometrically perfect orifices. This design ensures laminar flow characteristics and uniform water distribution.

Cheap nozzles, conversely, often have rough internal surfaces, inconsistent bore diameters, and poorly designed flow paths. These manufacturing shortcuts create turbulent flow patterns, resulting in uneven water distribution, irregular spray patterns, and reduced throw distances. The difference becomes immediately apparent when comparing side-by-side fountain displays.

Pressure Drop and Hydraulic Efficiency

Quality nozzles are engineered with specific pressure drop characteristics that match system pump capabilities. The relationship between inlet pressure, flow rate, and spray pattern is mathematically calculated and tested. This ensures optimal hydraulic efficiency and predictable performance across the entire operating range.

Local cheap alternatives typically lack this engineering rigor. Without proper pressure drop calculations, these nozzles either require excessive pump pressure (increasing energy costs) or fail to achieve desired flow rates and spray heights. The hydraulic mismatch creates system inefficiencies that compound over time.

Material Science: Why Construction Matters

Corrosion Resistance and Longevity

Professional fountain nozzles utilize marine-grade stainless steel (316L), bronze, or specialized polymer composites chosen for their corrosion resistance in water environments. These materials maintain dimensional stability and surface finish integrity over years of operation, ensuring consistent performance.

Cheap nozzles often use inferior materials like mild steel with basic coatings, low-grade aluminum, or recycled plastics. These materials corrode, pit, or degrade when exposed to water chemicals, minerals, and UV radiation. As the internal surfaces deteriorate, flow characteristics change dramatically, leading to progressively worse performance.

Precision Manufacturing Tolerances

High-quality nozzles are manufactured to tight tolerances (typically ±0.05mm) using CNC machining or precision molding processes. This accuracy ensures that orifice dimensions, internal geometries, and mounting interfaces remain consistent across production runs.

Budget alternatives often exhibit wide manufacturing variations due to inferior tooling and quality control. When orifice diameters vary by even 0.2mm between nozzles, the resulting flow differences create visibly uneven fountain displays where some nozzles overperform while others underperform.

Common Performance Failures

Uneven Spray Patterns

The most visible symptom of cheap nozzle failure is inconsistent spray patterns across multiple fountain heads. This occurs due to manufacturing variations, internal flow disruptions, and material degradation. What should be a symmetrical, pleasing display becomes an chaotic arrangement of varying water heights and patterns.

Clogging and Maintenance Issues

Cheap nozzles often feature designs that trap debris, algae, and mineral deposits. Poor internal geometries create dead zones where particles accumulate, gradually restricting flow. Quality nozzles incorporate self-cleaning features and smooth flow paths that minimize maintenance requirements.

Premature Wear and Replacement Costs

While cheap nozzles have lower upfront costs, their rapid degradation creates expensive long-term consequences. Frequent replacements, increased maintenance labor, and system rebalancing costs quickly exceed the initial savings from choosing budget alternatives.

The Hidden Costs of Cheap Nozzles

Energy Inefficiency

Poorly designed nozzles require higher pump pressures to achieve desired performance, increasing electrical consumption significantly. Over a fountain's operational lifetime, these energy costs can exceed the price difference between cheap and quality nozzles.

System Imbalance

When individual nozzles perform differently due to manufacturing variations or wear, the entire hydraulic system becomes imbalanced. This forces pumps to work harder, creates uneven water distribution, and may require expensive system modifications to correct.

Professional Reputation Impact

For commercial properties, hotels, and public spaces, fountain performance directly impacts visitor experience and property aesthetics. Uneven, poorly performing fountains reflect negatively on management quality and attention to detail.

Making the Right Investment

Quality fountain nozzles represent a long-term investment in reliable performance, reduced maintenance, and operational efficiency. While the initial cost may be higher, the total cost of ownership—including energy consumption, maintenance labor, and replacement frequency—strongly favors premium components.

When selecting fountain accessories, consider factors beyond initial price: manufacturing precision, material quality, hydraulic efficiency, and manufacturer support. Partner with suppliers who understand fountain hydraulics and can provide technical guidance for your specific application.

Your fountain deserves components that match its aesthetic ambitions. Choose wisely, and enjoy years of consistent, beautiful water displays that enhance your space and delight visitors.

Ready to upgrade your fountain performance? Contact our technical team for professional nozzle selection guidance and hydraulic system optimization.